Ⅰ.Nailan 6 allurar gyara tsari

1.Chemical da na jiki kaddarorin

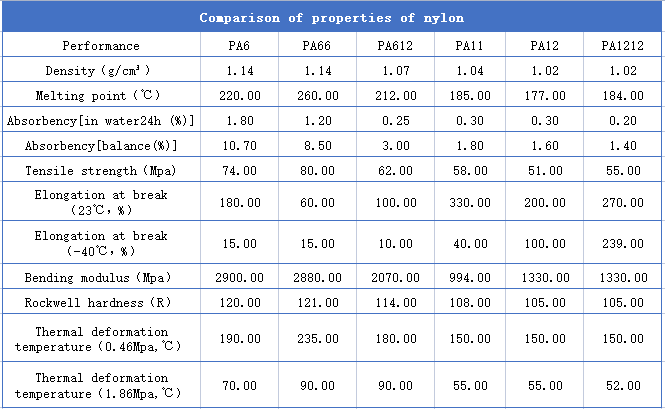

Abubuwan sunadarai da na jiki na Pa6 sun yi kama da waɗanda na Pa66; Koyaya, yana da ƙananan melting matsayi da kuma babban tsari na zazzabi mai ƙarfi. Tun da halaye masu inganci da yawa na sassan filayen filastik suna tasiri ta hanyar hygroscopicity, wannan ya kamata a la'akari lokacin da samfuran ke amfani da Passion ta amfani da PAS6.

Don inganta kayan aikin injin na PA6, galibi ana ƙara abubuwa iri-iri. Gilashin shine mafi yawan ƙari, wani lokacin kuma wani roba roba, kamar epdm da SBS, an ƙara wa SBR, ana kara su inganta juriya.

Don samfurori ba tare da ƙari ba, pa6 shrinkage yana tsakanin 1% da 1.5%. Additionarin karin fiberglass yana rage yawan ƙira zuwa 0.3% (amma dan kadan sama da perpendicular zuwa aikin). Maɓallin Shrinkage na Majalisar Molding na Mold Prodility ne yafi damun lu'ulu'u da hygrostcopicity na kayan. Ainihin ƙirar ƙasa shima yana aiki na ƙirar filastik, kauri bangon da sauran sigogin aiwatarwa.

2.Tsarin yanayin yanayin allurar rigakafi

(1) Jiyya na bushewa: tunda Paply ruwa a sauƙaƙe, ya kamata a biya ta musamman don bushewa kafin aiki. Idan ana wadatar kayan a cikin kundin ruwa mai ruwa, ya kamata a kiyaye ganga. Idan zafi ya fi 0.2%, ana bada shawarar bushewa cikin iska mai zafi sama da 80 ° C na 160 ° C na 16 hours. Idan an fallasa kayan ga iska fiye da awanni 8, ana bada shawara ga barasa a cikin iska mai zafi a 105 ℃ fiye da 8 hours.

(2) Yin zafin jiki: 230 ~ 280 ℃, 250 ~ 280 ℃ don karfafa iri.

(3) zazzabi m karfe: 80 ~ 90 ℃. Haramoda zazzabi mai mahimmanci yana shafar lu'ulu'u, wanda bi da bi yana shafar kaddarorin kayan aikin filayen filastik. Crystallity yana da mahimmanci don sassan tsarin, don haka da shawarar mold zazzabi ne 80 ~ 90 ℃.

Don sassan filastik na bakin ciki tare da dogon tsari, ana bada shawarar yin amfani da zazzabi mafi girma. Arfara yawan zafin jiki na ƙwararrun na iya inganta ƙarfi da taurin sassan filayen filastik, amma rage tauri. Idan kauri bangon ya fi 3mm, ana bada shawarar amfani da low-zazzabi na 20 zuwa 40 ℃. Don fiber fiber mai karfafa yawan zafin jiki ya zama mafi girma daga 80 ℃.

(4) Morectortion ARP: gabaɗaya 750 zuwa 1250bar (ya danganta da kayan da ƙirar samfuri).

(5) Speed Spration: High gudu (kadan ƙananan don inganta kayan).

(6) Runner da Gate: Matsayin ƙofar yana da muhimmanci sosai saboda gajeriyar lokacin zartarwa na PA6. Cirefar ƙofa bai zama ƙasa da 0.5 * t (inda t shine kauri na sassan filastik).

Idan ana amfani da mai tsere mai gudu, girman ƙofofin ya kamata ya zama ƙasa idan ana amfani da mai tsere na al'ada, kamar yadda mai tsere zai iya taimakawa hana ƙaddamar da kayan. Idan ana amfani da ƙofar ƙofa mai zurfi, mafi ƙarancin diamita na ƙofar zai zama 0.75m.

Pa6 allurar rigakafi

Ⅱ.nylon 66 allurar rigakafi tsari

1.Bushewa na Nylon 66

(1) bushewa: zazzabi 95-105 na awanni 6-8

(2) bushewar iska mai zafi: zazzabi 90-100 ℃ na kimanin 4 hours

(3) Crystadity: Baya ga nailan na crylon, na iya haifar da crystallen da sauran kaddarawa da kuma juriya na ruwa da kuma juriya na zamani da juriya. Matsakaicin zazzabi yana da tasiri mai tasiri akan lu'ulu'u, zazzabi mai tsayi mai yawan crystallity, ƙarancin zafin jiki mara nauyi.

(4) Ruwa mai yawa: mai kama da sauran rafin lu'ulu'u, Janar Nallon Shari ya fi girma, amma yanayin allura zai rage rashin daidaito. Kudin shrinkage na Pa66 shine 1.5-2%.

(5) Kayan aiki: nailan da hankali don hana "bututun ƙarfe da ya kwarara", saboda haka aiki na nailan abu gabaɗaya zaɓi bututun ƙarfe.

2.products da molds

(1) kauri na samfurori: tsayin tsayin nazanta shine tsakanin 150-200, bango mai kauri, da kauri bangon bango, mafi girman shrinkage.

(2) Gas (ciyawar iskar gas: da yawan ambaliyar ƙimar nailan resin kusan 0.03mm, don haka ya kamata a sarrafa shi a ƙasa 0.025.

(3) zazzabi m kankare: kayayyakin tare da bango na bakin ciki suna da wahala su samar ko suna buƙatar babban ƙarfin dumama, samfurin yana da sassauci na amfani da zafin jiki na sanyi.

Nylon 66 allurar alluna

3.Froring tsari na nylon 66

(1) zazzabi da zazzabi: saboda nailan lu'ulu'u ne mai narkewa, don haka m maidai bayyana a cikin allurar da aka zaɓa, kayan aiki, abubuwan fasalin samfurori. Nailan 66 shine 260 ℃. Saboda rashin lafiyar da mara lafiyar mara kyau na nailan, bai dace da zama a cikin siliki a babban zazzabi na dogon lokaci, don kada ya haifar da abubuwan da ake amfani da su ba bayan saurin kwarara.

(2) Ma'akarwar allura: na Nylon Santa yana da ƙarancin danko da ingantaccen ruwa, amma saurin saurin yana da sauri. Abu ne mai sauki ka sami isasshen matsaloli akan samfurori tare da tsari mai hade da bakin ciki bango na bakin ciki, har yanzu yana buƙatar matsin lamba mafi girma. Yawancin lokaci matsin lamba ya yi yawa, samfuran za su mamaye matsaloli; Idan matsin lamba ya yi ƙasa da ƙasa, samfuran za su samar da riples, kumfa, alamun fushin fushin ko kuma wadataccen kayayyaki da sauran lahani. Yawancin cututtukan cututtukan yawancin nau'ikan nau'ikan nailan bai wuce 120pta ba sama da 120pta, kuma zaɓi gaba ɗaya yana cikin kewayon kewayon 60-100mpsa don biyan bukatun yawancin samfuran samfuran. Muddin samfuran ba su bayyana kumfa ba, dents da wasu lahani, ba a tsammanin yin amfani da matsaka ta girma. Don kada a ƙara yawan damuwa na samfurin.

(3) saurin alluna: na Neylon, saurin allura yana da sauri, wanda zai iya hana tsaftataccen saurin da ya haifar da saurin saurin cika matsaloli. Speedirƙirar Yin allura Mai Girma bashi da tasiri mai mahimmanci akan kaddarorin samfurin.

(4) zazzabi m karfe: zazzabi mold yana da wasu tasirin akan lu'ulu'u da kuma mold shrinkage. Babban zafin jiki na ciyawa yana da babban lu'ulu'u, tsananin sa resistance, wuya, raguwar rashawa, da kuma shrinkage kayayyaki da yawa; Yawan zafin jiki m, zazzabi mai ƙarancin lu'ulu'u, tsananin tauri, babban elongation.

4.Nylon 66 forming tsari tsari

Ruwan zazzabi na ganga shine 240-285 ℃, tsakiyar zazzabi shine 260-300 ℃, kuma gaba zazzabi ne 260-300 ℃. A zazzabi mai ban sha'awa shine 260-280 ℃, kuma zafin jiki na mold shine 20-90 ℃. Matsarin allura shine 60-200mpta

Amfani da wakilin saki: Amfani da karamin adadin wakili wani lokacin yana da tasirin inganta da kawar da kumfa da sauran lahani. Titin saki na Nylon Products na iya zaɓar zinc na steoraate da fari, da sauransu dole ne a gauraye da manna, don kada ya haifar da lahani na samfurori. A cikin rufewa zuwa wofi dunƙule, don hana samarwa na gaba, dunƙule ya fashe.

Ⅲ.pa12 Moging tsari

1.pa12 yanayin tsari na tsari

(1) Jiyya na bushewa: ya kamata a tabbatar da zafi a ƙasa 0.1% kafin aiki. Idan kayan ya fallasa kayan iska, ana bada shawara a bushe a cikin iska mai zafi mai zafi na 45 zuwa 5 hours. Idan an adana kayan a cikin akwati na iska, ana iya amfani da shi kai tsaye bayan 3 hours na zazzabi daidaito.

(2) narke zafin jiki: 240 ~ 300 ℃; Karka wuce 310 ℃ don kayan tare da halaye na yau da kullun, kuma kar ku wuce 270 don kayan da ke tare da halaye na harshen wuta.

(3) zazzabi m karfe: 30 ~ 40 ℃ don kayan da ba a san shi ba, 80 ~ 90 ℃ don bakin ciki-walled ko manyan abubuwan haɗin kai, 90 ℃ 100 don kayan haɓaka. Extara yawan zafin jiki zai ƙara yawan lu'ulu'u. Yana da mahimmanci don pa12 don sarrafa daidai da zafin jiki.

(4) ARORSPRERTRACH: har zuwa 1000bar (low matsin lamba matsin lamba da zazzabi mai narke ana bada shawarar).

(5) Speed Spration: Babban saurin gudu (zai fi dacewa ga kayan tare da ƙari gilashin).

(6) Runner da Gase: Don kayan da ba ƙari ba, diamita na Runner ya zama kusan 30mm saboda ƙarancin danko. Don buƙatun kayan haɗin kayan da ke haɓaka na 5 ~ 8mm babban mai gudu diamita. Shafin Rushewa zai zama madauwari. Tashar allura ta zama gajeru yadda zai yiwu. Za'a iya amfani da nau'ikan ƙofar da yawa. Manyan sassan filastik ba su yi amfani da karamar ƙofar ba, wannan shine aurace matsin lamba na wuce gona da iri akan sassan filastik ko ragi mai yawa. Coaterarfin kauna yakamata ya zama daidai da kauri na sassan filastik. Idan ana amfani da ƙofar ƙofa mai zurfi, mafi ƙarancin diamita na 0.8mm an ba da shawarar. Motsin ruhu mai zafi yana da tasiri, amma yana buƙatar sarrafa yanayin zafin jiki don hana kayan daga lege ko ya inganta a bututun. Idan ana amfani da Runner mai zafi, girman gate ya kamata ya zama karami fiye da mai tsere mai sanyi.

Ⅳ.PAVE1010 tsari na tsari

Saboda NalLon 1010 Tsarin kwayoyin halitta ya ƙunshi ƙungiyoyi na hydrophilic, mai sauƙin ɗauka danshi, yawan amfanin ruwan shararsa shine 0.8% ~ 1.0%. Danshi mai mahimmanci yana da tasiri mai mahimmanci akan ainihin da na na inji na nailan 1010. Saboda haka, dole ne a bushe da albarkatun ƙasa don rage yawan abun ciki na ruwa zuwa ƙasa da 0.1%. A lokacin da bushewa na 1010 ya kamata ya hana bayanan oxidation na hazaka, saboda ƙungiyar Amide tana da hankali ga lalata oxygen. Zai fi kyau amfani da bushewa lokacin bushewa, saboda wannan hanyar tana da ragi mai narkewa, gajeriyar lokacin bushewa da ingancin bushewar granules. Yanayin bushewa gaba daya sama da 94.6 kpe na KPuum digiri, 90 ~ 100 ~ 7 ~ lokacin bushewa 8 ~ 12h; Abubuwan da ruwa ya ragu zuwa 0.1% ~ 0.3%. Idan amfani da tobal din bushe bushe, zafin jiki ya kamata a sarrafa shi a 95 ~ 105 ℃, kuma mika lokacin bushewa, gaba daya yana buƙatar 20 ~ 24h. Ya kamata a adana kayan bushe don hana tsawan danshi.

1.PAVE1010 tsari na tsari

(1) Tsarin aikin gona

Kafin shigar da ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwaƙwalwa ta 1010 ya isa ƙayyadadden zafin jiki na ƙayyadadden, kuma yana iya samar da isasshen adadin kayan molten, zazzabi mai narkewa yakamata ya zama uniform. Don saduwa da abubuwan da ke sama, ana amfani da na'ura ta allurar dunƙulen diski bisa ga halaye na Nylon 1010, dunƙule an rubuta shi ko nau'in maye gurbi. Zazzabi na ganga yana ƙaruwa daga wasan neman fafutuka. Saboda matsalar zazzabi na zazzabi kusa da melting batun yana dacewa da cigaba da karfin kayan, kuma yana iya nisanta lalacewa na kayan, kuma yana iya hana lalacewa na kayan, kuma zazzabi na kayan zafin jiki gabaɗaya 210 ℃. Don rage gogayya tsakanin dunƙule da pa1010 a lokacin da aka yi amfani da shi, ana iya amfani da ruwa mai ruwa da yawa, adadin yana da ƙarancin zazzabi gaba ɗaya 40 ~ 80 ℃. Theara yawan matsi na baya yana da dacewa don aiwatar da kayan a cikin dunƙule na dunƙule, cire ƙarancin motsi, amma karuwar matsin lamba na kayan aikin da aka yi zai rage. Tura da triped baya bai yi yawa ba, in ba haka ba zai rage ƙarfin da aka yi, har ma yana haifar da ƙarfin karfi na, saboda kayan lalata da yawa. Saboda haka, a karkashin yanayin haduwa da bukatun na allurar gyara, ƙananan filayen filastik shine, mafi kyau, gabaɗaya, gabaɗaya.

(2) Motsa Tsabtarwa tsari:

A cikin wannan tsari, hankali ya kamata a biya shi ga allurar rigakafin watsi da allon allon na 1010 allurar alluna. Gabaɗaya, matsin ƙyama ya zama 2 ~ 5psa, kuma saurin allura ya kamata ya zama mai jinkirin. Idan matsin cikin allura ya yi yawa sosai kuma saurin allura ya yi sauri, to yana da sauƙin samar da kumburin kumburi a cikin samfurin. Dangane da canza halayen matsin lamba na matsin matsin ƙyallen, ana iya raba tsarin allurar rigakafi a cikin matakan ciyar da mold, yana gudana da sanyaya. Za'a iya raba tsarin mai sanyaya zuwa matakai uku: yana riƙe da matsin lamba da ciyar da ciyar, da baya da sanyaya bayan daskarewa bayan daskarewa.

Wasu yanayi dole ne a hadu don ganin matsin lamba riƙe da kayan masarufi. A gefe guda, ya kamata mu tabbatar cewa akwai isasshen kayan molt, wato, akwai kayan da za a cika; A lokaci guda, tsarin simintin ba zai iya inganta sosai da wuri ba, saboda cewa kayan molten yana da hanyar da za a tafi, wanda shine yanayin da ya wajaba don sake fasalin kayan. A gefe guda, matsin allura ya zama mai girma kuma yana riƙe lokacin riƙe matsin lamba kuma ya kamata ya kasance da daɗewa, wanda shine isasshen yanayin don samun nasarar ciyarwa.

Lokaci na rike yawanci ana ƙaddara shi ne ta hanyar gwaji kuma ba zai yi tsayi da yawa ko maɗaukaki ba. Idan matsin yana riƙe lokaci yayi tsayi, ba kawai ya tsawaita sake zagayowar matsakaiciya ba, har ma yana da wahalar sakewa, ƙari, yana iya ƙaruwa da amfani da makamashi. Mafi kyawun matsin lamba mai kyau ya kamata ya zama babban matsin numfashi na rashin mutuwa ya zama sifili lokacin da aka buɗe. Gabaɗaya, matsin lamba na matsin lamba na Nightion 1010 sassa sassa 4 ~ 50 s.

(3) Remonding:

Nylon 1010 Za'a iya lalata sassan idan aka sanyaya a cikin mold don su sami isasshen tauri. Har yanzu zazzabi ya zama mai girma sosai, wanda aka sarrafa shi gaba ɗaya tsakanin yanayin zafin jiki na PAVE1010 da zafin jiki. Lokacin da ƙura, matsin iska ta hanzari na ƙirar ƙwayar cuta yakamata ya kasance kusa da sifili, wanda aka ƙaddara ta hanyar riƙe lokacin rike lokaci. Gabaɗaya, lokacin da aka gyara na pa1010 na alluna shine: allurar rigakafi 4 ~ 20 s, matsin lamba na rike lokaci 4 ~ 50s.

Source: Pa Nylon Masana'antu Sarkar

Lokaci: Mar-09-2023